Simple Way to Hook Up a VFD to a 13x40 Lathe

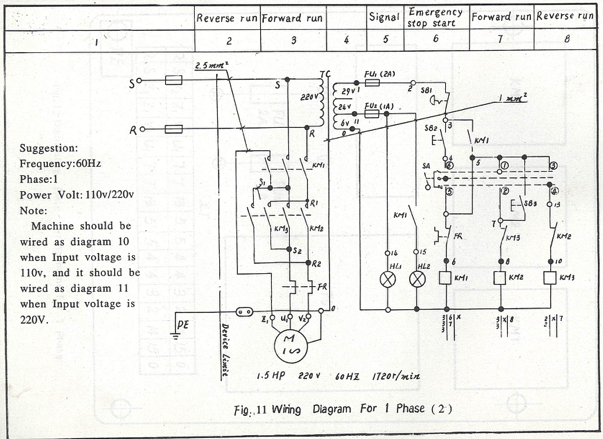

So Jerimy reached out to me last week for help with his Enco 13x40 lathe which is different from mine. His was designed with 3-phase input, and he wanted to be able to use it with the lathe controls and the VFD. But he had a problem; the VFD can't make 3-phase input power to the lathe, because the VFD output power should never be switched. I spent a few hours trying to track down his lathe wiring diagram, and make sense of the thorough wiring diagram he had traced out from his control box. I found several possible candidates for the diagram, and was going back and forth with Jerimy to see if we could figure out how to make it work. Then it finally occurred to me that it's really easy to hook up a VFD to most ENCO lathes (and probably many other Taiwanese/Chinese lathes. Here's the easy scoop. 1) You need to make sure that you run main power to the control box. If you have a single-phase lathe, that's easy -- just use the two conductors on the line in. If you